Case

Products

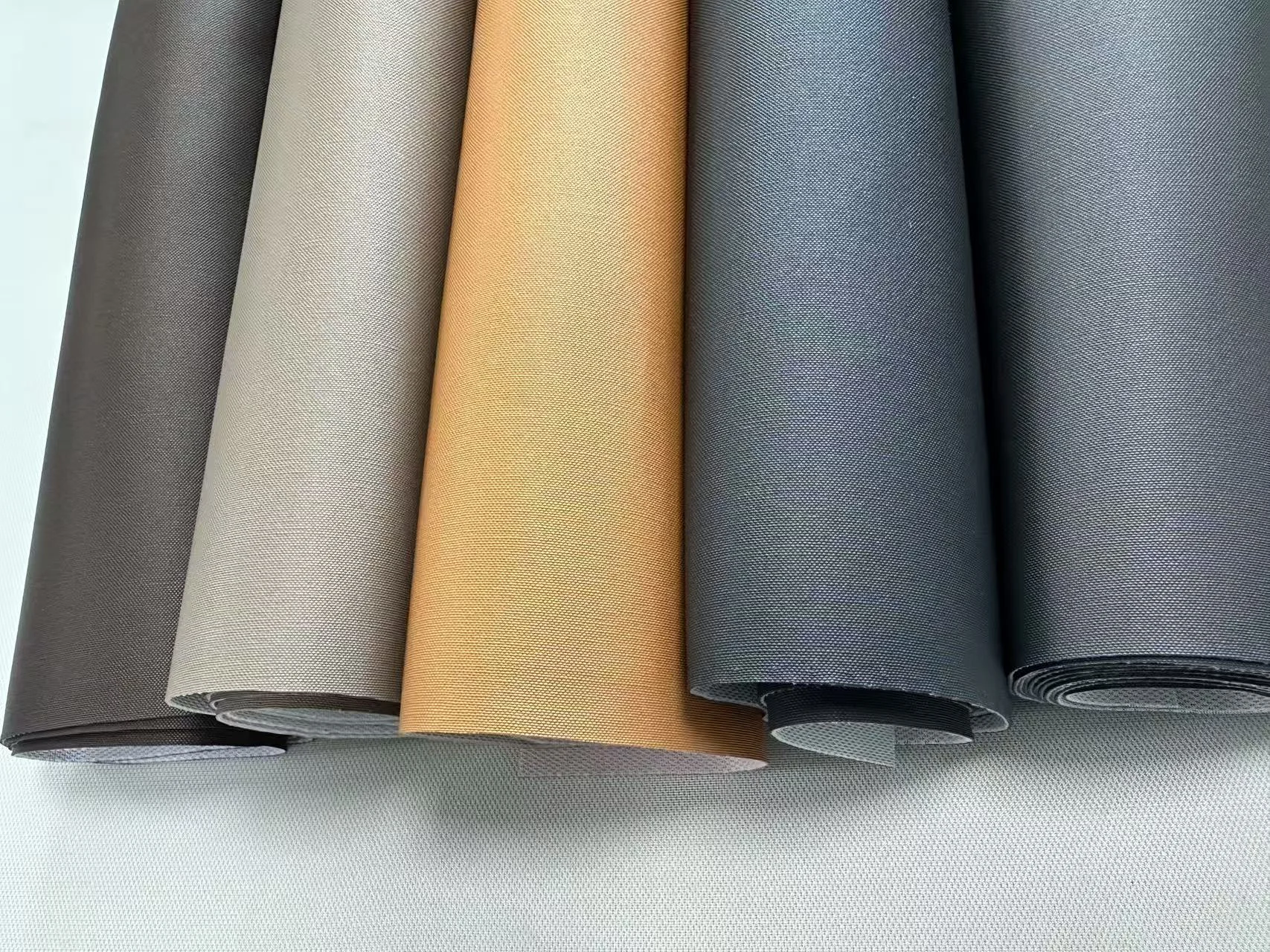

DN622 Outdoor yacht seawater-resistant flame-retardant V0 grade leather

DN622 Engineering the Future of Patient Care with Advanced Material Science

**Partner:** A leading innovator in patient support systems, developing next-generation medical beds for intensive care and long-term treatment facilities.

**The Pursuit of Excellence**

Our partner embarked on a mission to redefine the standard of care by designing a new line of medical beds. Their goal was to integrate superior patient comfort with uncompromising hygiene protocols and long-term durability, all while adhering to strict international safety and environmental standards. The critical component tying these elements together? The upholstery material.

**Material Challenges in a High-Stakes Environment**

The chosen material needed to be more than just a surface; it had to be an active contributor to patient safety and facility operational efficiency.

* **Hygiene Integrity:** Resistance to harsh, hospital-grade disinfectants without degrading or losing protective properties.

* **Infection Control:** Built-in, proven protection against a broad spectrum of microbes and fungi to minimize cross-contamination risks.

* **Durability Under Pressure:** Withstanding constant mechanical adjustments, patient movement, and frequent cleaning without cracking, peeling, or tearing.

* **Compliance & Safety:** Meeting global certifications for flame retardancy and the absence of harmful substances like heavy metals and VOCs.

**The Dashang DN622 Solution: A Synergy of Performance and Safety**

We presented **DN622**, our high-performance artificial leather, as a tailored solution. Its technical specifications directly addressed every challenge:

***A Fortress Against Chemicals:** **DN622** demonstrated exceptional stability when exposed to sodium hypochlorite, iodophors, and high-concentration alcohol, ensuring the material's integrity and appearance remain intact through thousands of cleaning cycles.

***Proactive Microbial Defense:** The integrated anti-microbial and anti-fungal agents provide 24/7 protection against prevalsent healthcare-associated pathogens, adding a crucial layer of safety.

***Engineered for Longevity:** With a martindale abrasion rating of 500,000 cycles, high tear strength, and proven resistance to hydrolysis (10-year equivalent), **DN622** is built to endure the demanding environment of a modern hospital, reducing long-term replacement costs.

***Certified Safety & Comfort:** The material complies with CAL 117 flame retardancy and RoHS 2.0/EN71-3 environmental standards. Its resistance to UV fading and consistent performance from -23°C to 80°C ensure patient comfort and a reliably professional appearance.

**Outcome: Elevating Product Value and User Trust**

By integrating **DN622**, our partner successfully launched a medical bed line that stands out in the global market.

***Enhanced Product Marketing:** They can confidently market the beds' durability, safety features, and ease of maintenance, backed by verifiable test data.

***Reduced Lifecycle Costs:** The exceptional durability of **DN622** translates to lower total cost of ownership for healthcare providers.

***Strengthened Brand Reputation:** Associating with a material that meets the highest standards of performance and safety reinforces our partner's position as an industry leader committed to quality.

**Conclusion**

The collaboration exemplifies how a strategic material partnership can be a catalyst for innovation. Dashang's **DN622** did not just solve a material requirement; it provided a foundation of trust, safety, and durability, enabling our partner to deliver a superior product that truly serves the needs of patients and healthcare professionals alike.

Related cases ![]()